Printing Gold with 3D Printing / Additive Manufacturing

June 18, 2020

Art Koch’s Profit Chain® Series

Volume 3 | Number 6 | June 2020

The Elegance of Simplicity

It was just last year when Apple Inc. (AAPL) announced that the company had exceeded a market value of $1 Trillion. How did they become the first company with a trillion-dollar valuation? It is my opinion that it was Steve Jobs’, and now Tim Cook’s, relentless focus on simplicity. Both understood that it would not be easy and that it would take unwavering tenacity to achieve their vision.

“Simple can be harder than complex: You have to work hard to get your thinking clean to make it simple. But it’s worth it in the end because once you get there, you can move mountains.”

— Steve Jobs

How does this concept translate to Operations and Supply Chain?

Let’s start with the fact that very few companies go from zero to $100 Million, or $1 Billion in valuation overnight. They start with a $50K or $100K purchase order, followed by a $200K or $500K PO, then the acquisition of a competitor, and before you know it, they’re at $100 million in sales.

The same is true of business process complexity. At the $50K to $500K in sales level, Operations and Supply Chain processes can be run with index cards & Excel spreadsheets. The processes that Johnny and Sally once used to maintain control are no longer adequate for a higher level of sales, more complex Bill of Materials, and the addition of international Suppliers & Customers.

Throughout my career, time and time again, I have heard from CEO’s and COO’s, who would claim that they needed to upgrade or implement a new ERP system. “This will fix the problem we’re having with customer service and/or inventory levels, and once it has been completed, everything will be good.” If only it was that simple.

The real issue is that we allow entropy to creep into our organizations.

en · tro · py /’entr?pe/ noun.

Lack of order or predictability; gradual decline into disorder.

The following are examples of Entropy Creep in your organization:

- A few suppliers turn into thousands.

- A few customers turn into hundreds or thousands.

- The number of raw and sub-assembly part numbers increases exponentially.

- The number of finished goods part numbers increases exponentially.

- The need to support service parts for 10 to 20 years after end of product life cycle.

- etc., etc…

Once entropy creep has occurred, it doesn’t take long before the team gets caught up in a failure spiral of just trying to keep up with daily tasks, never getting to the root cause of the complexity that’s consuming their time and energy.

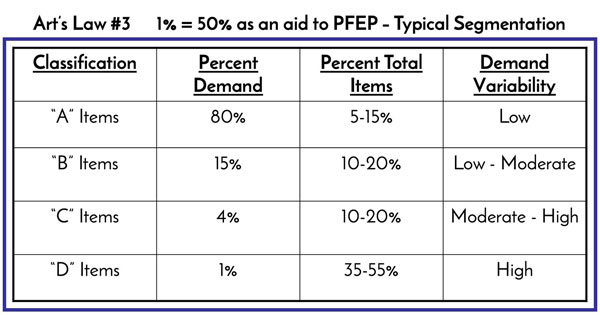

What if I were to tell you that for every business I have worked with, I completed the following analysis, and had the same outcome?

- The last 1% of purchases

- Represents 50% of the part numbers or suppliers,

- Or the last 1% of customer demand

- Represents 50% of finished goods part numbers and customers.

There is a myth that managers believe; “If you focus on the top 80% of the 80/20 rule, the results will come”. In the short-term, you can make the argument that this is correct. However, in the long-term, the results are not sustainable because the last 1% of demand is draining the team’s resources. We must shift the paradigm and focus on eliminating the drivers for the last 1% of demand, or 50% of the complexity.

What would your business look like if complexity was cut in half? Would you need complex ERP, CRM, and MRP systems? My argument is that you would not, and the reason we need such complex processes and operations that require exception after exception and tribal knowledge, is because of the sheer scope of our product offerings, and the parts required to support them.

Over the past 20-30 years, much has been written about accomplishments that have been made in all areas of business with satisfying customer expectations. We keep adding more and more product offerings, with greater functionality and in larger sizes, in many cases, without adequate processes in place to support such a large variety of choices.

Let’s take a hard look at ourselves and agree there is a tipping point where processes will not be capable of more variation or there needs to be a radical disruptive event that allows every increasing profitable product offerings. Again, look at Southwest Airlines and Apple. One firm is a discount air carrier, and the other is high-end consumer electronics manufacturer. Both are excellent examples of companies that are operating complex equipment with a simple business design, model and product offering. Surely your business can be designed to succeed without the last 1% of demand or 50% of the complexity?

Disrupt the Enterprise Leverage 3D Printing / Additive Manufacturing

Article upon article has been written about the advantages of complexity reduction, and the steps to be taken to accomplish it.

However, what if your business model is to have the product complexity, i.e. the service parts industry. Your business model is to supply and support customers for decades after the final product has rolled off the assembly line. How could you build the supporting business processes with radically reduced complexity without sacrificing the product offering complexity?

Stop thinking of a process, a committee, or a new initiative for complexity reduction. Tell the team and your customers that you’re eliminating the stocking of the last 1% of demand, and instead, you will manufacture on demand.

Blow up the current model. The latest business buzzword is “Disruptive”. Be disruptive! Be Entropy Busters®! What would this mean for your business design, organization, supply, and customer base?

The Elegance of Simplicity with 3D Printing / Additive Manufacturing

How can 3D Printing transform your supply chain and operations to reduce the Total Cost of Ownership?

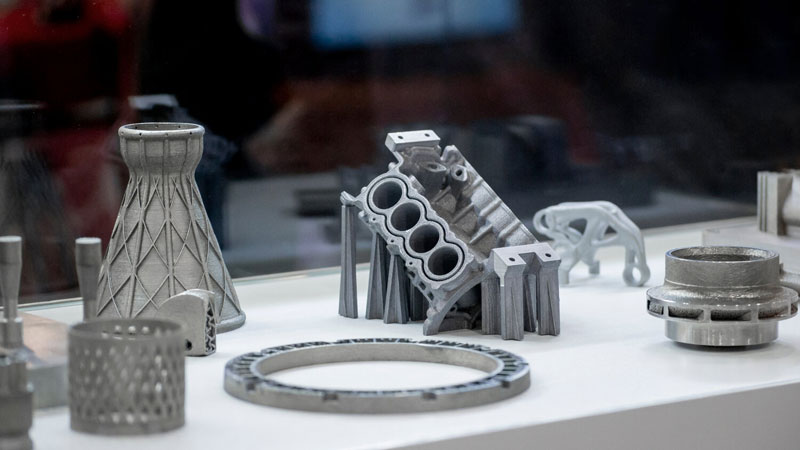

- Reducing inventory. Service parts inventory is expensive to maintain; with obsolesce, damage, spoilage, and shrinkage, all at significant costs. When printing on demand, there will no longer be a need for warehouse and storage space. There will be a 60% to 100% long-term savings for every dollar of inventory reduction.

- Supply Base changes. There will no longer be the need to keep hundreds or thousands of suppliers to support the last 1% or 2% demand and niche items. Think of the complexity reduction in supplier negotiations, supplier data management, logistic management, accounts payable, etc.

- Lead-time Reduction. If printing on demand, there will no longer be the supplier and raw material lead-times. Just print time!

- No More Minimum Order Quantities’. Once the part is designed and the CAD drawing is saved, the part can be printed on demand for material cost.

- No More Tooling Cost. With 3D printing, the fixtures and jigs of traditional manufacturing are no longer required.

- Print at Demand Source. Reframe traditional thoughts on manufacturing. Have 3D printers at the source of demand, eliminating costly and lengthy transportation and customs clearance processing.

- Machine Complexity Reduction. Eliminate the complex machine shops used to produce a wide array of parts. One 3D printer can be used for multiple purposes, and when procured to the proper specifications, it should satisfy most of your needs.

- CAD Design, Customization, and Accuracy. With the use of CAD, the engineering team will have greater design freedom, customization, and the ability to meet the most demanding tolerance requirements.

The first 3D Printers were available in 1986, we now have 30 plus years of refinement to our advantage, so I absolutely believe that we are at the inflection point for the of adoption of 3D / Additive Manufacturing for service and, intermittent and lumpy demand parts. The ramifications for transforming the Total Cost of Ownership and disrupting the competitive supply chain stage are immense. For early adopters, this moment in time presents an opportunity similar to the industrial revolution and the first industrial use of the transistor. Are you ready to print GOLD?

Entropy Busters®

“Stop letting the process manage you! Become the champion of your game plan and achieve sustainable profits.”

I would like to give special thanks to Danny Davis for recommending this newsletter. If you have any suggestions for future newsletters, please e-mail or call to discuss ideas.

Categorized in: Art Koch Profit Chain® Tips