Positioning Supply Chains for the Raging 2020s

March 27, 2021Art Koch’s Profit Chain® Series

Volume 4 | Number 3 | March 2021

How about implementing Warp Speed in your Supply Chain?

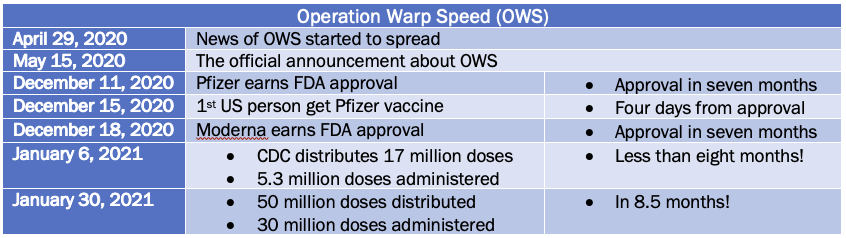

Former US President Trump’s administration initiated Operation Warp Speed in March of 2020. The goal was to get multiple COVID-19 vaccines FDA approved within nine months. To put things in perspective, the typical time to bring a vaccine from development, clinical trials, production, and finally to administered doses is ten years! Not only was the goal achieved, but they were also able to ramp up vaccine production to 100 million doses at a rate of one million per day within 30 days of approval.

Most would agree this was an extraordinary achievement accomplished through a highly coordinated effort between governments and private industry, no matter your political convictions.

The exact way this task was accomplished brings forth an excellent case study in partnerships that are easily translatable to your business and can help your company maneuver through the turbulent changes in customer purchases and consumption patterns.

Elements for Partnerships

There are typically five critical elements that partnerships should have to be successful:

- Improved collaboration

- Risk reduction

- Improved velocity to market

- The agreement must be mutually beneficial to both parties

- The reduced total cost of ownership

OWS did an excellent job addressing three of these five elements: risk reduction, improved collaboration, and improved velocity to market.

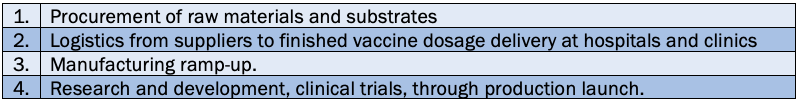

When studying OWS challenges, we can see they used standard program management techniques from new product development through product launch, dividing the process into four distinct swim lanes.

New Product Introduction Swim Lanes

For OWS to be a success, it required near-flawless execution within each swim lane, and those exact steps can be used by any business to integrate partnerships and manage change.

Within the procurement swim lane, the US government guaranteed the buyback of any unused materials. They also did a deep dive into their sub-suppliers production capabilities and made strategic, almost surgical, investments in supply chain and manufacturing deficiencies. This process allowed manufacturers to significantly reduce the supply chain risk, thereby shorting lead times.

In the logistics swim lane, a combination of the private sector and government completed a cold storage distribution network upgrade. Capacity was added, and staff increased to handle the demand for the -40 Celsius storage requirement for the vaccine and the production of 500 to 600 million doses. In addition to expanding the physical infrastructure, the OWS team mobilized the military supply chain and medical teams to deliver and administer the vaccine.

New pharma plants were built within the manufacturing swim lane, and existing facilities were retrofitted to manufacture the COVID-19 vaccine. New production lines and cells were implemented to manufacture and package the new vaccine. We must understand that this was a Herculean accomplishment. Even in their June 1, 2020, COVID report, McKinsey cautioned that it would normally take five years to bring a pharma production facility online.

All pharmaceutical companies piloted multiple vaccines through research and development swim lanes utilizing R&D and clinical trials to arrive at one vaccine for FDA approval.

We must remember OWS compressed the typical vaccine approval lead-time from ten years to nine months without knowing the exact vaccine formula.

Additionally, OWS addressed three of the five elements of partnerships:

- Risk Reduction. The US government-funded and advanced purchase orders eliminating nearly all risks to private industry.

- Mutual Benefit. OWS opened channels of communication and collaboration between manufacturers and regulatory agencies.

- Velocity to Market. The private sector delivered viable vaccines quickly at industrial production levels to inoculate entire counties within nine months!

These elements, overall, allowed manufacturers to significantly reduce their total risk within the supply chain, thus shorting lead times.

The most powerful lesson learned here is that using partnerships reduces risk, improves collaboration, and increases velocity to market. These are the fundamentals of any good supply chain.

Supply Chains Turned Upside Down and Inside Out

As we entered into the COVID-19 pandemic, most people did not know what to expect. Many businesses were fighting for their survival. Market segments such as air travel and hospitality demand dropped 80 to 90%.

In hindsight, it made perfect sense that products such as home office, home improvement, and personal exercise equipment would see increased demand. However, in an almost parallel universe, demand for boats, personal watercraft (Jetski), and roller skates sky-rocked.

While manufacturers were struggling to understand the shifts in demand, the food supply chain was turned upside down. There are two discrete swim lanes within food supply chains; one for home and the other for restaurant consumption. We saw product shortages for home consumption and spoilage in the restaurant supply chains because we were quarantined to our residences. It took several months to get everything flowing efficiently from suppliers who had only sold to restaurants and institutional buyers to transition to swim lanes for home consumption.

As if these seismic demand shifts weren’t enough, supply chains were equally disrupted by whole countries closing their borders, regional governments closing non-essential businesses, and individual facility closures due to workers contacting the COVID-19 virus.

Post Pandemic Demand Planning

As we exit the COVID-19 pandemic, intelligent businesses are already positioning themselves for post-pandemic demand shifts. The most important questions are:

- What percentage of employees and how quickly will they move back to their offices?

- How long-term are the government stimulus packages, and how swiftly will employment grow

- How quickly will the travel and hospitality industry rebound?

- How quickly will consumers forget about the Covid-19 period’s high-demand items like boats, Jetskis, and roller skates?

- How well do you know your market, and what products or services will see demand increases first?

- Longer-term, what impact will inflation have on an economy attempting to move back to a normal state?

I believe that some products will have a defined V-shape demand profile, and others will transition gradually. However, it won’t be the inverse of when the pandemic first hit. International borders will need to open, goods will need to flow freely, and there will continue to be fewer regional government and business closures. The port backlog will clear, and international freight costs will normalize. The world’s supply chain will continue to be fragile for twelve to eighteen months, and issues like the Suez canal blockage will not significantly impact the global economy.

However, innovative businesses will place themselves ahead of the planning curve and capture demand from the sleeping competition.

Transferring These Lessons to Your Business

What steps can you take to use partnerships, both forward and backward, in the supply chain to reduce risk and to be ready for the Raging 2020s of economic growth post-COVID-19?

First, identify a few strategic partners. These partners can be both suppliers and customers who improve your performance and make you more competitive. Understand that you only need a few. Trying to establish too many partners can drain the organization of valuable resources.

Second, to the best of your ability, identify products or families of products where demand could likely “take-off” in the post-COVID-19 economic boom.

Third, take these steps to reduce the risk to the supply chain as follows:

- Reduce the dependency on forecasting by using finished goods, work-in-process, and raw materials authorizations. Using this methodology will reduce lead-times and total pipe-line inventory. Additionally, this process helps avoid using raw materials and machine capacity on finished goods that customers don’t need.

- Procure raw materials that could go on allocation, and that can be manufactured into multiple finished products. This recommendation is for both your manufacturing sites and suppliers. I would recommend securing this material in your warehouses.

- Have boots on the ground to physically track your orders at suppliers, and make sure you’re getting the parts you purchased.

- Secure capacity on critical bottleneck machinery at suppliers.

- Find suppliers closer to your final assembly sites. Taking this step involves insourcing, on-shoring, and near-shoring.

- Hire talented supply chain, operations, and trades associates.

Forth, improve communications and collaboration between all teams involved. Create channels for daily communication. I am not talking about using e-mail here. Establish triage meetings for the tasks that need to be completed immediately to make the next 12, 24, 48, and 72 hours successful. Use, but don’t overuse KPIs. Focus on the relevant few that facilitate two-way information sharing from the shop floor to leadership, suppliers, and customers.

Your “project warp speed” reduces the risk in the supply chain, meets and exceeds customer expectations, and establishes sustainable growth. By following these simple process steps, you will reduce lead-times, reduce the risk of building the wrong product and reduce the total cost of ownership.

Additional reading from Fierce Pharma, “What does it take to supply COVID-19 vaccines across the globe?”

Art Koch’s Profit Chain®, Entropy Busters® and The Inventory Doctor® are the registered trademarks of Arthur Koch Management Consulting, LLC.

Turning Operational Problems into Profits SM, Inventory Is Evil! SM and Unlock the Art of Change SM are pending trademarks of Arthur Koch Management Consulting, LLC

Categorized in: Art Koch Profit Chain® Tips