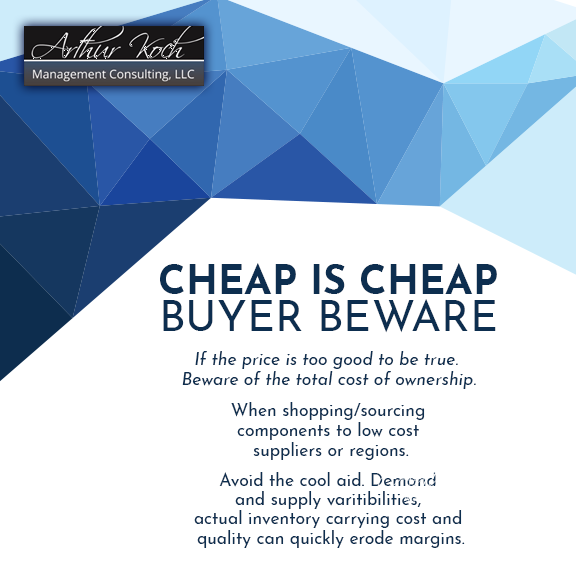

Let’s start with the realization that plan “A” to relocate operations to China had a major flaw. If you moved manufacturing to China, India or any other low- cost producing country with the intention of importing goods back to North America or Europe (half a world away), then your plan was unsound!

I was taught to do everything possible to reduce lead-times and increase inventory velocity! Why is this important? Longer lead-times increase inventory. More inventory equates to less profits. Why? Because inventory delays fixing problems. When I see corporations chasing the labor “ghost”, I cringe! Labor typically accounts for 8-12% of the total cost of ownership. But too many leaders only have one play in their play book: to reduce labor costs by moving head count to low cost countries! They are missing 90% of the total cost of ownership!

Read article