The Call of a Generation – Navigating the Covid-19 Crisis

March 18, 2020Art Koch’s Profit Chain® Series

Volume 3 | Number 3 | March 2020

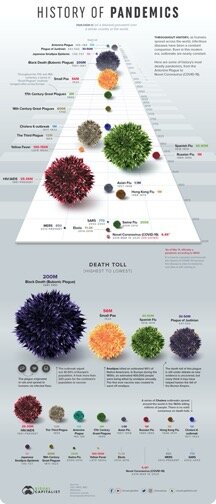

As our parents, grandparents, and great-grandparents before us, each generation was called on to make sacrifices for their country: whether it was during World Wars, The Great Depression, or similar pandemics such as the Spanish Flu. Today, WE are the generation who must make the sacrifices. We will get through this as stronger people, stronger nations and partnerships. Please remember, as bad as this feels, no one is dropping bombs on us or shooting at us!

This is a very complex, fluid situation, and white papers could be written on each area outlined. However, for the sake of time and necessity, I’ll try to outline the critical key points to help you and your team navigate the current developments. Below, I have broken down the core competencies, skills and tasks into several categories:

Short Term: As a manufacture, what can be done now?

Leadership. Leadership must be rock solid in the face of crisis. This is a time for, as the Brits say, a “stiff upper lip”. Leaders need to guide the team though difficult obstacles, barriers and decisions. Leadership is a “Contact Sport”. Now is the time to be seen, heard and physically part of the solution. Understand that we are all in this together. This crisis crosses over all social and economic barriers, all geo-political boundaries, and both natural and man-made international borders. We, as leaders, need to be unbroken, resolute, fearless and the shining light guiding your company to future success.

There is good news and bad news. As CEOs, we are learning how to become better leaders through this Global Health crisis’. This is our new reality: a known unknown. As the world continues to be more connected and economically entwined, the crises are not going away and may even become more frequent. For the good news: with each passing crisis, we improve. Healthcare infrastructure and disaster recovery planning improves, resulting in a less of a substantial global impact.

Establish a triage team to manage the crisis.

Three important questions need to be answered:

- What are you trying to solve and/or accomplish?

- Take a deep breath.

- Don’t overreact.

- Decipher through large amounts of misinformation.

- Be leaders and educate your team.

- What are your priorities?

- You will need cash to weather the storm. Think of approximately 10-12 weeks of cash.

- HR Policy

- Work from home, etc.

- Essential team member who must work.

- Keeping your customers.

- Building loyalty.

- Establishing Goodwill.

- Establish a “No Group Think” mentality. There needs to be open and candid discussions.

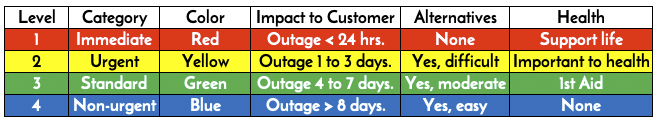

Prioritize the threat

Priorities Suggestions

Outline the risk by attribute:

- Country and Region.

- Customer and Supplier.

- Part number.

- Base and raw material. If you feel the threat is high, buy up the stock if it non – perishable.

Select the team:

- Procurement.

- Supply Chain Demand and Supply Planning.

- Manufacturing operations.

- Traffic and logistics.

- Engineering.

- Quality Assurance.

- Sales and Marketing.

Be proactive.

This is the time to win the hearts and souls of your customers. This is not a time to gouge or make excessive profits. Long term customer loyalty based on great products, corporate values and goodwill, have a far greater return than just short-term ROI.

- Think outside the box. If you’re a restaurant have 5-Star Pick-Up and Take-Out windows with great service, fresh food and limited to no contact.

- Start working with customers to get approval to change manufacturing locations.

- Buy capacity ahead of time.

Don’t waste the opportunity: A Crisis or Recession is a Terrible thing to Waste

Lately, much has been written about the impending economic downturn and the need to recession-proof your business.

I vehemently disapprove of this! It’s as though if you say something often enough, it will happen. The doomsayers will all jump up and down to say, “look I was right”! What they may have forgotten is that recessions are a natural part of the economic cycle. Much like birth, death, and taxes, they will always occur.

Circling back to recession-proofing, I equate the concepts of recession-proofing your business with the game plan of playing football using the “not to lose plan”. I’ve been a big fan of University of Michigan’s men’s football team for many years. During Bo Schembechler’s tenure as the Wolverines head coach, he would get a nice lead in a game then change the strategy from an aggressive offensive mode to a defensive “not to lose” mode. When doing this, you can dramatically and negativity shift the team psyche. Before you know it, the other team has the emotional upper hand, and possibly the lead. Why is this done at all? Lack of confidence or playing too conservatively?

Let’s re-frame our focus, take a hard-right turn and ask ourselves the following question: Why waste a perfectly good recession? When times are booming, what’s the one resource we all could use more of? TIME! We can’t get to the problems because we’re too busy making money. In addition, problems are often hidden within the sheer volume and growth.

When the inevitable recession starts to poke its ugly head around the corner, let’s not slip into the defensive game plan of “not to lose”. It’s the game you lose most of the time. Let’s take this hard right turn I’ve been referring to and double down on problem resolution in the areas that keep your organization from achieving its full potential.

Invest, invest, invest!

- In training and development, shore up any existing gaps to skills and core competences.

- Hire for any gaps in skills and core competencies you can’t develop. They might be at a bargain.

- Double down on improvements to:

- Inventory velocity. Always remember, Inventory Is Evil!™. Why? Because, it hides and delays problem resolution. There is no better time to challenge conventional wisdom on inventory levels than during a recession.

- Challenge and reduce current lead-times from suppliers and deliveries to customers.

- Rationalize the supply and customer base. Remember my Rule of 1% = 50%.

- Address scrap, first pass yield, internal and external PPM quality shortcomings.

- Complete any maintenance that has been delayed.

- Expand capacity through change over reduction, first pass yield improvements, machinery additions, and business acquisitions.

Lastly, instead of squeezing the vendor for price reductions, take the opportunity to build partnerships with both suppliers and customers that will jointly reduce the total cost of ownership, Art Koch’s Profit Chain®.

Run the ROI. Numbers don’t lie! This is the best course of action.

The path of least resistance is to cut costs. That’s for amateurs! Build your business case for the CFO. It’s hard work, but anything worthwhile is always hard work. That is what a winner will do to be a champion!

So, Mobilize your team! Come out swinging and become more competitive than previous months.

A recession is a terrible thing to waste!

As a consumer:

- Don’t panic. We live in a time of abundance.

- Do you really need the brand name?

- Shop on line.

- Reconnect with the family and nature.

Long Term:

Manufacture and assemble regionally for regional customers.

If you moved manufacturing to China, India, or any other low-cost producing country with the intention of importing goods back to North America or Europe (half a world away), then your plan was unsound! Focus on inventory velocity, total cost of ownership, and the ethics of investing. Now we are in the middle of a S^&% storm of COVID-19 with world-wide impact to supply chains and the global economy.

Let’s become great at preventing the inferior solution. So that being said… how is Plan “B” for your China supply chain coming? Like many, you have been ignoring the warning signals. Now there is a “burning” platform. Are you ready to act? Use this event as your “All Hands-on Deck”, “Battle Cry”, or Winston Churchill moment.

What lessons can we learn?

- Focus on long-term and not quarterly profits.

- Don’t ignore the warning signs.

- Avoid group think. Just because other organizations are “doing it” does not mean it’s a good idea. As the guardian of an enterprise, there is a requirement to think beyond the current frame of focus.

- We need to think regionally.

- Focus on inventory velocity, part and process quality, and become a zealot for total cost of ownership.

- Software providers have done an excellent job of “selling” integrated supply chain solutions. However, how integrated can your enterprise be with 90 to 120 days of total pipe line inventory?

- Manufacture products regionally for regional customers.

- The stewardship of low-cost country sourcing.

- Imagine customer loyalty when your enterprise keeps products and services flowing when others can’t?

We are in the middle of this new global threat. I hope and pray for a quick recovery. Those of you who know me well, I’m an optimist. However, if we don’t act now to protect our enterprises from the next threat, it could just be the BIG one. I would hate to have to say I told you so, again.

What is your Plan “B”?

Don’t be afraid to ask for help!

Self-Ranking – Pick one of the four questions below and then fill in your comments in the space provided.

- Don’t think this applies to your business or enterprise? (Write three to four reasons why it might not.)

- This is a new idea and strategy, it’s something we need to work toward. (Brainstorm the first steps.)

- We can do better, modify our strategy, and now we are moving in the right direction. (What are the next steps to ensure success?)

- Our team gets the necessary time to keep their minds fresh and we have plans to live our dreams. (Comment on how you’re ready.)

- ___________________.

- ___________________.

- ___________________.

- ___________________.

Categorized in: Art Koch Profit Chain® Tips

Tags: , Art Koch's Profit Chain®, COVID-19, Crisis, Leadership