Wuhan’s Butterfly Effect on Supply Chains

September 20, 2021Art Koch’s Profit Chain® Tips

Volume 4 | Number 8 | August 2021

It’s rapidly approaching two years now (November 2019), when COVID-19 was circulating in the area of Wuhan, China infecting the first cluster of humans. Since the first reported outbreak of COVID-19, it’s been an incredibly crazy experience all over the world. However, that first cough or sneeze was likely the cause of the current global supply chain disruptions.

but·ter·fly ef·fect

(in chaos theory) the phenomenon whereby a minute localized change in a complex system can have large effects elsewhere.

– Oxford Dictionary

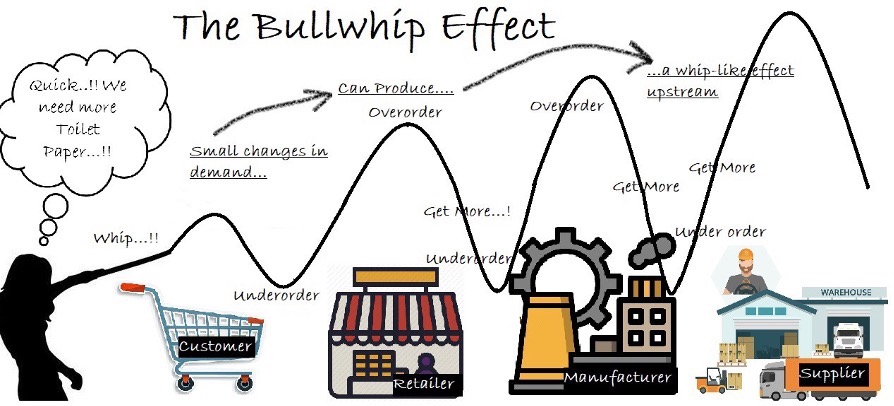

bull·whip ef·fect

Also known as the “Whiplash Effect,” it is an observed phenomenon in forecast-driven distribution channels. The oscillating demand magnification upstream of a supply chain is reminiscent of a cracking whip. The concept has its roots in J Forrester’s Industrial Dynamics (1961), and thus it is also known as the Forrester Effect.

– Council of Supply Chain Management Professionals

Many world governments instituted “stay at home” orders, lengthy home quarantines, or “lockdowns during that same period.” When these measures took effect, consumer demand patterns that were once very predictable vanished. Worldwide non-essential manufacturing stopped. Demand for PPE and essential home goods such as toilet paper, paper towels, and soup increased exponentially, while the actual use of these items had not increased to any great extent. Consumers wanted more of what they could not get. As a result, we experienced the bullwhip effect.

When every economic indicator was pointing south toward imminent recession and the pandemic was taking hold worldwide, international ocean freight companies used the opportunity to cull and scrap their fleets of inefficient vessels.

Then, the unthinkable happened. The economy does not just come to a screeching halt! We witnessed the miraculous four to six-week transformation of the supply chain “swim lanes” from perishable food products consumed by restaurants and institutions to completely different products demanded by families working from home. Large segments of the population working and schooling from home needed computers, microphones, monitors, lights, and everything associated with a comfortable and efficient place of work and study. Our supply chain professionals rose to the cry of duty and turned what could have been a disaster into a huge opportunity.

When everyone settled into homeschooling and working from home, western consumerism took hold in the form of home improvements, kitchen and bathroom renovations, artwork, painting interior walls, new floors, etc. As Zoom and Microsoft Teams took over our computer monitors, many became self-conscious, which started a fitness craze; bicycles, weights, exercise equipment, and personal watercraft demand skyrocketed. Supply chain professionals scrambled to fulfill customer demand after the once predictable demand patterns, and supply chain swim lanes were turned upside down.

As if the disruption from the COVID-19 pandemic wasn’t enough, let’s not forget about the “Great Texas Freeze” and the Suez Canal blockage of 2021. Individually, either of these events would strain some portion of a regional supply chain. However, in conjunction with COVID-19, they caused significant reverberation throughout global supply chains that are still being felt months later.

Finally, the delays of ships waiting to be unloaded have little to do with increased imports and traffic making way to cargo ports, but more with a lack of resources further upstream in the logistics process. For two decades, the United States Department of Labor projected a shortage of long-haul truck drivers, which never materialized until the COVID-19 pandemic (the same is true for the EU). Many drivers used the opportunity to reassess their desire to be home with spouses, children, and grandchildren, leaving the workforce or working short-haul routes. Additionally, the Federal Motor Carrier Safety Administration disclosed that 60,299 CDL holders have drug or alcohol violations that bar them from operating a commercial truck. What’s striking about this data is that it is nearly the same number of drivers needed to fill the current commercial driver shortfall. – Freight Waves To further complicate the situation, there is a shortage of intermodal chassis and warehouse space to store incoming goods. These constraints are a bottleneck along our domestic supply chain, and if not addressed with more drivers and chassis, will negatively impact economic growth.

Did “the sneeze heard around the world” disrupt global supply chains? Absolutely! The next time you see a butterfly effortlessly floating through the air, or you forget to cover your mouth when sneezing, remember one flap of the butterfly’s wings or errant sneeze can change the course of history!

I want to take time to recognize the supply chain professionals who are working diligently to hold the world’s economy together. I’ve made a career of helping people and organizations overcome their supply chain opportunities. I can tell you firsthand that too often, the individuals tasked with the improbable job of keeping food on our tables, hospitals stocked with supplies, and cars in our garages don’t always have the necessary resources to succeed. However, what we are witnessing with the pandemic is a testament to their grit, fortitude, and resiliency. Please accept my THANK YOU to you and your entire family for the hard work and sacrifices over the past eighteen months.

Categorized in: Art Koch Profit Chain® Tips