The Three Fs of Supply Chain Management

November 20, 2020Art Koch’s Profit Chain® Series

Volume 3 | Number 11 | November 2020

During my supply chain management career, I’ve learned and understood how our roles support the Board of Directors. The Board of Directors are charged with two key elements that supply chain professionals can impact: risk mitigation and shareholder value. We reduce risk by building sustainable processes, inclusive teams, and developing supplier partners. We improve corporate valuation by lowering the total cost of ownership (TCO) and increasing inventory velocity.

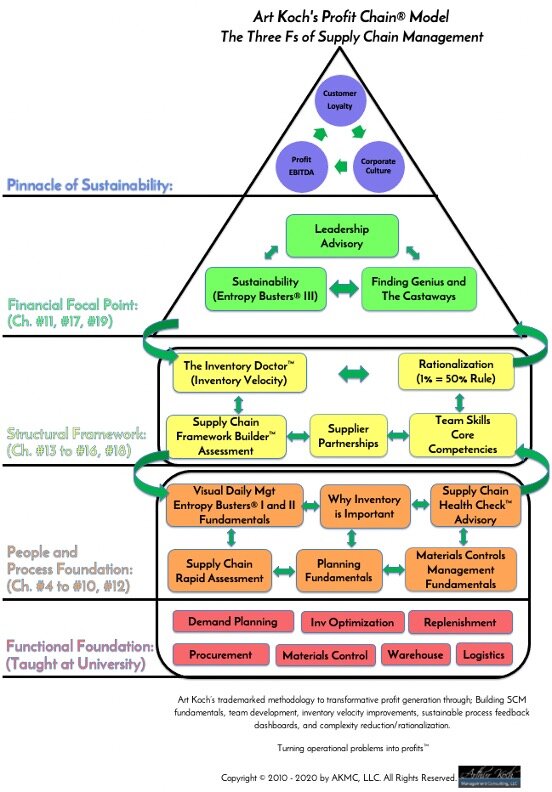

As a supply chain leader, I’ve learned to execute the Board’s charter; we need a robust technical foundation that universities do an excellent job of teaching. I’ve discovered that universities don’t bridge the gap between theory, real-world application, and expected corporate outputs of Customer Loyalty, Corporate Culture, and Profit. To resolve this dilemma, I’ve created Art Koch’s Profit Chain® Model – The Three Fs of Supply Chain Management – see diagram below. The content overlooked is the core body of knowledge on applying textbook theory and examples to real-world applications. I call these the Three Fs of Supply Chain Management;

· People and Process Foundation.

· Structural Framework.

· Financial Focal Point.

The bottom section of the model is the Functional Foundation taught in universities. The top section is the Pinnacle of Sustainability that are the deliverables from everything below.

Functional Foundation:

Building from the bottom up is the Functional Foundation that is much like the cement footers of a house. The Foundation consists of the primary functions within supply chain management. These are the courses taught in Supply Chain Management programs at universities.

In general terms, each function looks to be very straightforward, so, in principle, it should be easy to transition from textbook to the real-world. However, it is not so simple for many reasons; with procurement, it’s not just placing a purchase order and then having parts magically arrive. Valued manufacturing takes place, a product is shipped, and as a result, we have happy customers.

People and Process Foundation:

The next level up in the model from the Functional Foundation is the People and Process Foundation; think of it like the bricks that support the structure of the house. In the simplest terms, these are the lessons learned from university teachings that are translated and applied to business and operations management real-world processes.

Within the People and Process Foundation, there are six methodologies:

-

Supply Chain Rapid Assessment for benchmarking the current status of SCM.

-

Supply Chain Health Check Advisor to sustain the current state and reach stretch objectives. The emphasis here is on using rapid assessment processes to secure the commitment for change and then using a structured follow-up process to “health” check the team’s status and the need for corrective actions.

-

Planning Fundamentals of scheduling, replenishment, and demand utilizing classification methodology to significantly improve customer service and inventory performance.

-

Why Inventory is Important to any organization and Material Controls Management Fundamentals explain how to systematically improve your inventory accuracy by following six fundamental pinch points.

-

Entropy Busters® Phase I and II utilizes Visual Daily Management to improve communications, teamwork and achieve rapid results.

Structural Framework:

So far, we have built the People and Process Foundation. The next step is the structural framework, which is similar to the house’s frame that holds the structure together. Once there is a firm foundation and framework, we can work at an advanced capacity in the application of business processes and practices to step functionally improve the business. Within this framework is where the refinements and the details emerge in real-world applications.

Within the Structural Framework, there are five methodologies:

-

Team Skills and Core Competencies will help you determine the required skills and competencies needed in the supply chain organization to become the industry leaders in their profession.

-

The Supply Chain Framework Builder™ Assessment identifies gaps within qualitative and quantitative supply chain practices that keep the organization from becoming world-class.

-

The Inventory Doctor® (Inventory Velocity) enlightens the negative impact of inventory on profits, customer service, and problem resolution; then transitions into The Inventory Doctor® on how to diagnose and improve inventory performance.

-

Art’s Law #3 of 1% = 50%, we examine how 1% of purchases or demand can account for 50% of complexity and offer simple solutions to correct this challenge.

-

Supplier Partnerships illustrates the importance of transforming your relationships from vendors to supplier partners and how accomplishing this accelerates the organizational competitive advantage.

Financial Focal Point:

The final piece in the model is the Financial Focal Point, just below the roof peak. This part consists of the convergence of the processes and methodologies that catapult the organization ahead of the competition. In doing so, we accomplish completing the closed-loop model of sustainability, getting leadership to excel by building inclusive teams, and the ongoing leadership advisory to break away from industry peers, turning your supply chain into a competitive advantage.

Within the Financial Focal Point, there are three methodologies:

-

Entropy Busters® Phase III for increasing sustainability of processes.

-

Finding Genius and The Castaways, how to discover hidden stars in the organization.

-

Leadership Advisory is how to select and work with experts that help leaders achieve personal and professional growth and life balance.

Art Koch’s Profit Chain®

Create dramatic improvements to inventory velocity, customer service, and corporate profits.

With the disruption from the COVID pandemic, it’s even more critical to understand and apply the methodologies from Art Koch’s Profit Chain® Model to your; resourcing, insourcing, nearshoring, and reshoring strategy.

Categorized in: Art Koch Profit Chain® Tips